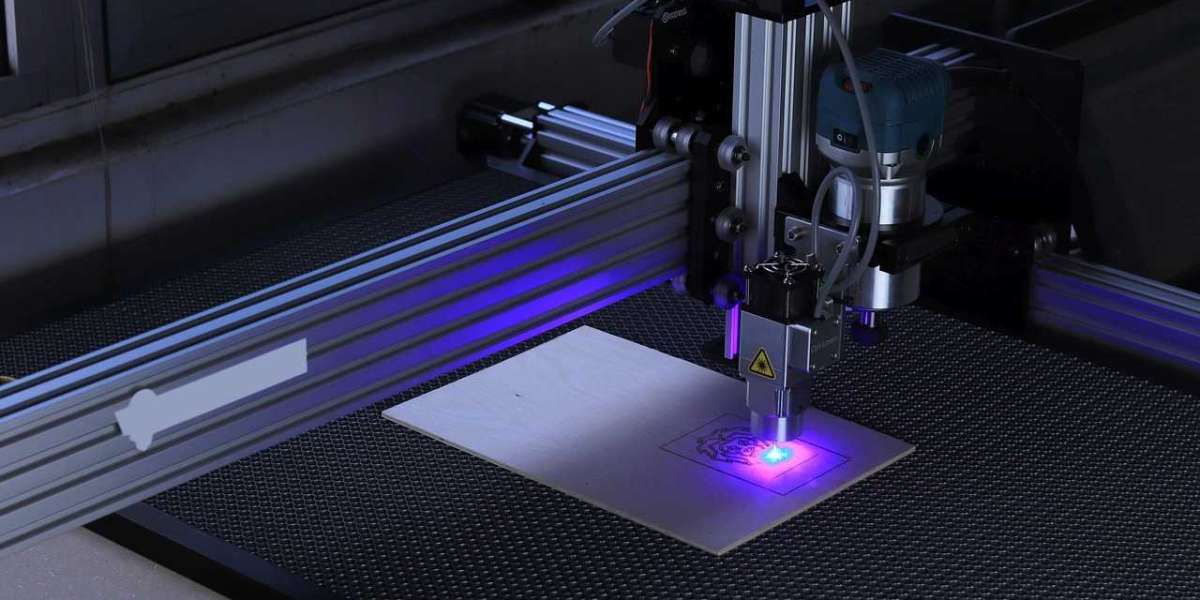

engraving has revolutionized the way we personalize, create, and mark various materials. With its precision, speed, and versatility, engraving has become a preferred method for crafting intricate designs, adding brand logos, personalizing items, Laser Engraving industrial components. From small businesses to large manufacturing industries, laser engraving offers solutions that are both practical and creative. This guide delves deep into everything you need to know about laser engraving, including its processes, applications, materials, and benefits.

1. What is Laser Engraving?

a. Understanding the Basics of Laser Engraving

- Laser engraving is a process that uses concentrated light energy to mark or etch patterns, text, or designs onto a surface. This is achieved by directing a laser beam, which vaporizes a layer of the material, creating permanent, high-precision markings without physical contact.

b. Differences Between Engraving, Etching, and Marking

- While these terms are often used interchangeably, they each have distinct meanings in the world of laser technology. Engraving involves removing material to create a noticeable depth; etching slightly alters the material’s surface, while marking only changes the material’s color without removing any surface.

2. How Does Laser Engraving Work?

a. The Laser Beam Process

- Laser engraving systems use a high-energy laser beam directed through mirrors and lenses to focus on a specific point. As the laser interacts with the material, it generates heat that vaporizes the material, creating a groove or indentation on the surface.

b. CO2 Lasers vs. Fiber Lasers

- Two main types of lasers are used for engraving: CO2 lasers, ideal for non-metal materials, and fiber lasers, designed for metals and tougher surfaces. The choice of laser type depends on the material to be engraved and the desired outcome.

c. Software and Computer Control

- Most laser engraving machines are connected to software that allows users to upload designs, adjust settings, and control the engraving process with high precision. The software translates digital designs into instructions for the laser, ensuring accuracy.

3. Popular Applications of Laser Engraving

a. Personalization and Customization

- Laser engraving is frequently used to personalize items like jewelry, mobile phone cases, plaques, and awards. It allows for custom designs, names, logos, and messages, providing a personal touch to gifts and keepsakes.

b. Industrial and Manufacturing Uses

- In manufacturing, laser engraving is used to mark parts, create barcodes, and ensure traceability. The automotive, aerospace, and medical industries often rely on laser engraving for precision marking on components and tools.

c. Artistic and Creative Projects

- Artists and designers use laser engraving to create intricate patterns on wood, glass, leather, and more. From wall art to custom furniture, laser engraving adds a layer of uniqueness and creativity to various artistic projects.

d. Signage and Branding

- Companies use laser engraving for signage, nameplates, and brand logos on various surfaces. It provides a durable, high-quality finish that stands out and remains visible over time, even in challenging conditions.

4. Materials Suitable for Laser Engraving

a. Metals

- Laser engraving works exceptionally well on metals, including stainless steel, aluminum, brass, and titanium. It creates precise markings that withstand wear, making it ideal for tools, jewelry, and industrial parts.

b. Wood

- Wood engraving is popular for decorative purposes and custom furniture. Different types of wood (like maple, cherry, and pine) can be engraved to produce beautiful, intricate designs that add texture and personality.

c. and Crystal

- engraving on glass is often used for awards, drinkware, and décor. The laser creates a frosted effect on glass surfaces, allowing designs to stand out without compromising the material’s transparency.

d. Plastics and Acrylics

- Engraving on plastics is common in the production of signs, nameplates, and promotional items. Certain plastics, like acrylic, offer a clean, smooth finish that looks professional and is durable for indoor and outdoor use.

e. Leather and Fabrics

- Leather engraving is popular for wallets, belts, and fashion accessories. Certain textiles, like denim and cotton, can also be engraved for unique patterns and designs in fashion and branding.

5. Advantages of Laser Engraving

a. Precision and Detail

- Laser engraving provides high levels of precision, enabling intricate and complex designs that other methods cannot achieve. This makes it ideal for applications requiring fine detail, such as jewelry and electronics.

b. Durability and Longevity

- Laser engravings are permanent, withstanding wear, fading, and environmental factors. This makes them ideal for industrial applications where long-lasting marks are crucial.

c. Fast and Efficient Production

- Laser engraving is a quick and automated process, especially when combined with computer-aided design (CAD) software. This efficiency benefits businesses that require high-volume production with consistent quality.

d. Environmentally Friendly

- Laser engraving is often more eco-friendly than traditional engraving methods. It requires no inks, chemicals, or physical contact, reducing waste and the need for maintenance on cutting tools.

e. Versatility Across Materials

- The versatility of laser engraving extends across a wide range of materials, allowing businesses and creators to work with multiple substrates without needing different engraving methods.

6. Key Considerations When Choosing a Laser Engraving Machine

a. Purpose and Application

- Consider what you’ll primarily use the laser engraver for—personal projects, small business, or industrial purposes. CO2 lasers are suitable for non-metal materials, while fiber lasers are better for metals and heavy-duty tasks.

b. Machine Power and Speed

- Higher wattage results in faster engraving speeds and the ability to cut deeper. However, higher power is not always necessary for detailed engravings, so choose based on your application’s needs.

c. Software Compatibility

- Ensure the laser engraving machine is compatible with design software you’re comfortable using. Many machines support common programs like CorelDRAW, Adobe Illustrator, and CAD software, providing flexibility for different design needs.

d. Maintenance and Support

- Some machines require more maintenance than others, so consider a model with minimal upkeep if you prefer convenience. Additionally, choose a machine from a manufacturer known for excellent customer support and training resources.

7. Tips for Achieving High-Quality Laser Engravings

a. Preparing Your Design

- Optimize your design for engraving by using high-resolution files, as low-quality images may result in blurred or pixelated engravings. Vector graphics are ideal, as they scale without losing clarity.

b. Choosing the Right Settings

- Settings like speed, power, and frequency play a crucial role in the quality of the engraving. Conducting test runs and using manufacturer-recommended settings for each material can help achieve the best results.

c. Maintaining Your Laser Equipment

- Regularly clean your machine’s lenses, mirrors, and cooling system to ensure consistent performance. Dust and residue can accumulate over time, affecting the engraving quality.

d. Experimenting with Different M engraving allows for creative experimentation. Trying out different materials and settings can yield unique results, adding value to your projects and expanding your product range.

8. Future Trends in Laser Engraving Technology

a. 3D Laser Engraving

- 3Dengraving, which creates depth and a layered effect, is gaining popularity. This technology is particularly useful in creating intricate designs on crystals and other transparent materials.

b. Portable and Compact Laser Engravers

- With advances in technology, portable laser engravers are becoming more common, making it easier for hobbyists and small businesses to create high-quality engravings without large machinery.

c. Integration with AI and Automation

- AI is being incorporated into laser engraving systems, allowing for automated quality checks, adjustments, and faster production. This integration is expected to improve precision and reduce errors.

d. Environmental Innovations

- As demand for sustainable practices grows, laser engraving technology continues to evolve with eco-friendly innovations. Newer systems are designed to minimize energy use, reduce waste, and make engraving more sustainable.

Conclusion

Laser engraving has become a game-changer in the worlds of art, manufacturing, and personalization. Its ability to produce precise, durable, and intricate designs on a wide variety of materials makes it an essential tool across industries. From crafting custom gifts to marking industrial components, laser engraving provides flexibility and precision that meet diverse needs. With ongoing advancements in technology, the possibilities for laser engraving continue to expand, opening up new creative and functional applications.